Research and Development

TRL's principals have a history of using R&D to explore concepts and to provide the basis for putting those concepts into metal. Over $2,100,000 has been expended over the years for R&D and development of our concepts.Synergistic Recovery System™ & Ore Research Program

From 1981-1984 Cyril L. Wood (1929-2003) undertook explorations into overcoming the shortcomings of a chemical leaching system using Action Mining's CLS leaching product after spending time at their facility located in sourther CA at the time. Woody was trained as an assayist and learned about the CLS leach system at the time. Lucite test tanks were built to observe the flow of materials in the tank and the efficiency of agitation systems. Larger conical tanks were purchased and adapted to allow testing of larger samples of ore and place cons. Retention time, recovery, and agitation methods and protocols were established.

Ore studies and sample testing were accomplished on ore and placer cons samples solicited from Alaska's active mining operations during this period. Two major breakthroughs enabled the use of this system reliably, but only as a batch system. The system called Synergistic Leaching System™ (SLS™)was very effective on high sulfide ores carrying precious metals. One advantage of the system was that the precious metals did not have to be taken into solution and exchanged out before recovery. Recovery of free milling metals was immediate. The average leach time was five hours from start to finish. Recovery was generally >=105% of fire assay, depending upon the composition of the ore matrix. The largest test tank would process 300lbs of ore cons. Over $250,000 was expended on the R&D.

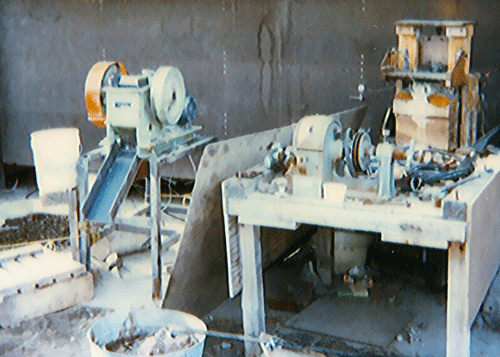

We had a fairly complete mineral test unit consisting of a 5X7 jaw crusher, a 3X4 lab jaw crusher, a 9IN plate grinder, a waterjacket mercury retort, a complete Denver flotation system and a 2 ton per day ball mill, a fire assay lab and small batch Synergistic™ test cell for mineral leaching tests and assay comparisons.

Cyril L. Wood (1929-2003) was an assaysist and served as a 3d party referree assayist at the request of Bob Pollack, Metallurgist and Mine Manager for Enserch's Lucky Shot Mine in Hatcher's Pass.

Arctic Miner™

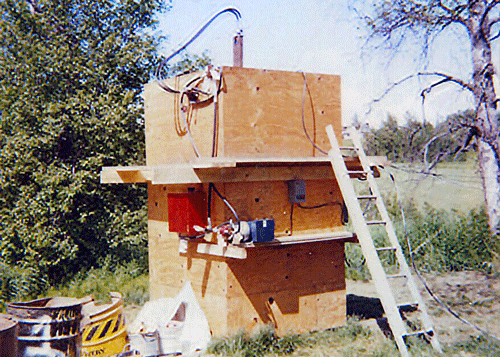

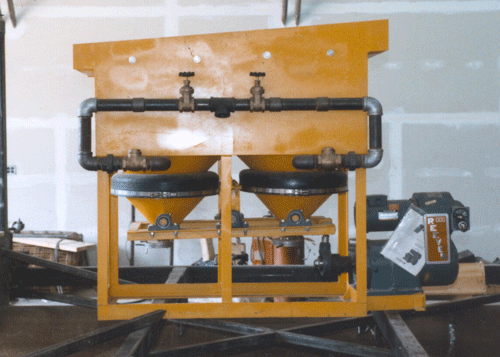

The Arctic Miner™ alluvial recovery system was developed in 1985 by Cyril L. Wood (1926-2003) and Lawrence D. Wood in response to ever more restrictive alluvial mining water quality constraints and the knowledge that sluice boxes lose gold. This fact is substantiated by some properties in Alaska being mined for the 4th time by mechanical means using sluice boxes as the primary recovery method. Further, water use and the necessity of settling ponds can limit the ability to operate in some areas.The Arctic Miner™ flow sheet reduces system water requirements, and enhances fine gold recovery. Pan-American type duplex mineral jigs reduce water usage and increase fine gold recovery. Make-up water is for system loses is reduced considerably.

In its final configuration, the prototype Mk242 recycled 98.6% of its water and made make-up water requirements of <=10gpm are possible. Recovery of 95% of +150 gold was also demonstrated with the Arctic Miner™ flow sheet.

Fine gold recovery is the object of the Arctic Miner™. The Arctic Miner™ is also trade-named Gravimetric Reciculating (Mineral) Recovery System: GRRS™ for short. The Arctic Miner™ was the first Alaskan built multi-stage mineral recirculating multi-stage mineral jig system built in Alaska in 1985-1986. The first Arctic Miner™ was the Mk242.

The largest Arctic Miner™ being a 90CY/hr primary jig capacity system built on a Euclid S10 scraper chassis, named "Erma the Euc".

Arctic Miner™ units can be built to capacities of several hundred cubic yards per hour.

Terra Wash™

Terra Wash™ is a mobile soil washing solution for cleaning contaminated soils. Since initial development in 1991 by Cyril L. Wood (1926-2003) and Lawrence D. Wood, Terra Wash™ has been used on military and private sector soil washing and Small Arms Firing Range cleanups in Alaska, Hawaii and the Midwest. Terra Wash™ incorporates several attributes of both the Synergitic Recovery System and the of the Arctic Miner™ concepts. Lucite test tanks were built and used to determine the effectiveness of agitation, need for heat, and to determine the best tank design for system mobility. As a result, the Terra Wash™ Soil Washing Units are flexible as to configuration and have been tested on inverts and crude oil contaminated bentonite drilling muds, "sludge" sands from oil sands in Alberta, crude oil and fuels contaminated alluvium and silt.

We have tested PCB contaminated soils from Saglek, Labrador, Canada, thermally shocked soils from Cook Inlet waste pits, North Slope waste pit materials, and conducted a 5 month test and R&D program to evaluate surfactants for use on invert remediation. Invert remediation R&D conducted in B.C. and Alberta, Canada in 2009 demonstrated that Terra Wash™ can clean contamined shale cuttings. We conducted SAFR remediation and closeouts to test the Arctic Miner™ flowsheets for this application.